In my previous post, we covered the fundamentals of restaurant back-end operations, compared them with the paint industry (with similar operations) operating profitably by adopting scientific methods.

We will go a bit deeper into the restaurant space, talk about ingredients and yields and how lack of ‘process and technology’ adoption is affecting their profitability. These are my observations, having spent considerable time in many kitchens, and the example presented below is real.

Yield:-

Defined in percentage, the part of the ingredient that is ‘actually’ usable against the purchase weight. Many ingredients needs trimming before use and you will lose parts of it — called as trim loss. And this will vary depending on season, geography, quality and various other conditions.

Say, if we take cauliflower weighing 1 kg and trim the leaves and stalk (apparently these are edible), you will be left with around 850 grams. Essentially,

APQ — As Purchased Quantity = 1000 grams

EPQ — Edible Portion Quantity = 850 grams

Yield = EPQ/APQ = 85%

Why is this important ?

We will take a sample recipe with Basa fish as the ingredient. Basa is imported from Vietnam, comes frozen or ‘glazed’ in ice. The glazing factor is generally mentioned on the box.

In our kitchens, we were used to buying frozen Basa at INR 240 a kg, sounded like a good deal and no tax (these happen). The price was good and fish was tasty. Was there anything to complain — absolutely ! We were just buying it too frequently and I was left wondering why. Our average portion had about 160 grams of base fillet and with an yield of 60–62% (post thawing, trimming — you get about 600–620 grams) it meant we could do about 4 portions of a dish. We got in touch with another sea food supplier who quoted an atrocious INR 280 + 5.5% VAT — that’s INR 295.5. I argued with him that his price is 23% higher than what my current purchase price. Doesn’t make sense, does it ?

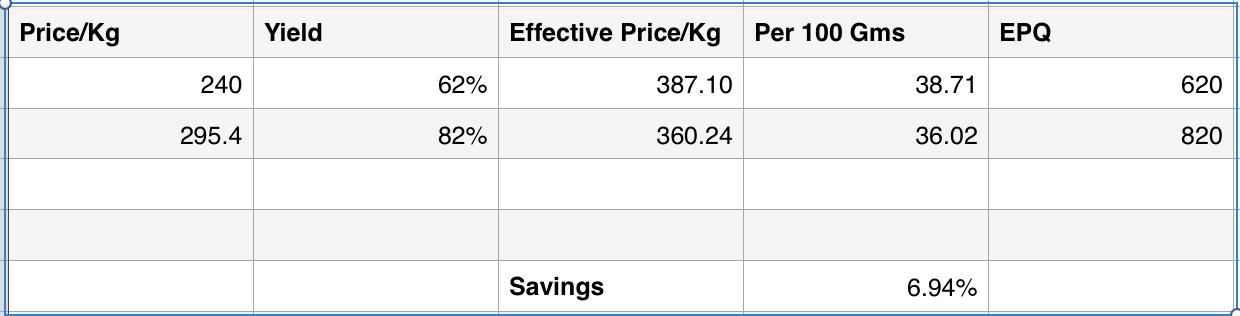

He asked me to check the glazing factor and asked me to check the yield. We bought few samples and tested their yield. It was a neat 82–84%, though the box claimed 10% glaze. I immediately replaced the old vendor with this one — why ? As usual a picture is worth a thousand words. There you see, a savings of 7% and effective rate per kg is INR 360, as opposed to INR 387. And you could do 5 portions of the dish as opposed to 4 earlier.

Let us take a dish that sold well for us and contains this ingredient to see how it would affect your margins with both prices.

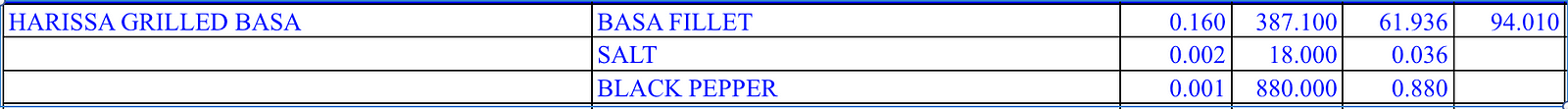

COGS — Old price @ 387.1/kg

*Full recipe below, above is shortened for brevity, all other ingredients retained.

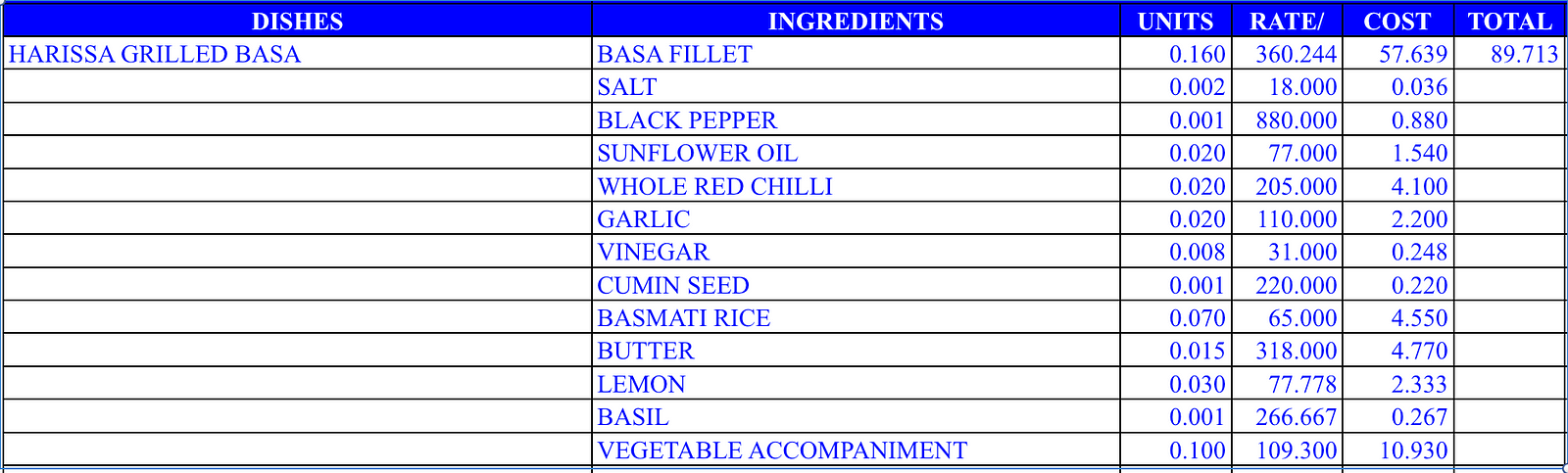

COGS — New price @ 360/kg

Thats a neat savings of INR 4.30 per dish, roughly 4.6%. If you are selling about 20 of these on a daily basis, that’s a cool INR 2580 per month saved. This 4.6% directly affects your gross margins and net margins. As they say in good old poker, “Money saved is money earned” !

And this is just one dish, one ingredient, we haven’t even engineered other ingredients in the list ! And yes, we haven’t moved to other dishes that have similar issues.

Any restaurant that with a top line of about INR 25–30 Lakhs, with a PAT of 15–20% (4.5–6 lakhs a month), will have inventory costs in the range of 9–11.5 lakhs, with 0.38 COGS factor, which is what we observed across many outlets. Even at 0.33 COGS, you are looking at 8.25 to 10 lakhs of procurement. Now leaving aside myriad other parameters that go into food costing and savings, we just bring the yields into play, leading to a saving of approx 5%. You are potentially saving anywhere from INR 41K to 50K per month. These get added directly to your gross margins leading to higher profitability. Let’s assume you made Rs. 30 as PBT, 20 as PAT, now you are making 35 PBT and 23.33 PAT, which in terms of percentages is a cool 17%. Many of the restaurants are losing money and they don’t know, which otherwise is there for you to take. Why would you want to lose money ?

More insights later. Thanks for reading.

Planning to build a restaurant operational manual? Read our guide about what components to include in your restaurant operations manual.