Before getting into what EagleOwl is and how it helps your business, allow me to rewind the clock and take you through the birth and journey of Honey Badger Labs.

After 15 years of pure coding in the tech industry, a combination of boredom, despondency and palpable frustration had set in. I wasn’t really enjoying my job anymore and wanted to learn and do things that I wasn’t exposed to. After an year filled with multiple failures to change line, an opportunity came by where I was asked to take care of the operations of a full stack food tech company in Bangalore. It helped that the CEO was my poker buddy for 5–6 years. The role was exciting and challenging, domain was completely new and I loved it.

For a change I got to work out of kitchen — constant noise, heat, plastic chair and full-on action compared to the boring AC rooms, superficial meetings, fancy desks I was accustomed to. I spent time understanding the business and the people for a few weeks and was initially tasked with taking care of kitchen operations (food cost, procurement, OpEx). After a month, my CEO asked to handle delivery and packaging in addition to above. It would only be fair to say that I had zero knowledge or experience of every single aspect listed above.

Initial days and problems:-

Our sales those days (Sept/Oct 2015) were average, but we were procuring items so often and couldn’t account for that frequency. There wasn’t any process or tool to track purchases in our kitchen. Invoices were filed and sent to accounts team for payment. A simple math of purchase to sales led to a high food cost of about 60–65%. We knew this was bad and had to be controlled, target was set to 35% and within a month. Though we had recipes created by Chef, they weren’t adhered to, costing was wrong and ingredient choices were awry. Also purchase was random, we had too many stocks in the kitchen, there were stocks that were never used for months, there were expensive (perishable) stocks that were purchased for a dish that sold 1/2 per day, at best. To summarise, following were some of the initial problems:

- High Food Cost

- Recipe — Inaccurate costing, bad COGS ratio, wrong choice of ingredients

- Procurement — Random, over stocking, unused stocks, too many stocks, wastage

- Selling Price — Low, ad-hoc.

- Vendor pricing — no negotiation, single vendor for a SKU category, minimum order values, delivery challenges.

Though they look like different issues, all are tied to each other in kitchen operations. In most businesses, people know the cost of production of the item/service they are offering. So they add the desired margins and fix a selling price. Else the business isn’t sustainable. One fundamental issue we noticed was that we didn’t accurately know how much each of our item costed, also we were also under the illusion that our selling price was scientific based on wrong recipe and costing. This had to be corrected quickly.

We sat with our Chefs and edited the recipes for items that were selling well to ensure we maintained the desired margins. This is the easier part, the line staff were then trained and educated in parallel to ensure adherence to new standards and measures. We could then measure the outcome for those items in a week. In parallel, we initiated talks with more vendors for each category and started bringing the cost down. We also spoke to various hoteliers and restaurateurs in our area to establish connects with more vendors. This had the desirable effect and we were able to bring down our procurement cost quickly for many items.

A real scenario:-

Some of our chicken (breast boneless) dishes were doing well, especially European Non Veg section where our average quantity was about 140–150 grams per portion. A back of the envelope calculation on procurement to sales ratio showed something amiss. We had to find out what was happening.

A variance report helps identifying the actual vs expected consumption and whether you are losing money or a customer (under utilisation). This is the best way to detect supply or purchase frauds, over/under use in recipes, wastages. For the items that sold well for us we took physical stock of few important ingredients and recorded in our excel sheet. We started recording all purchases in the same sheet. After a week we conducted physical stock taking for the same list of ingredients.

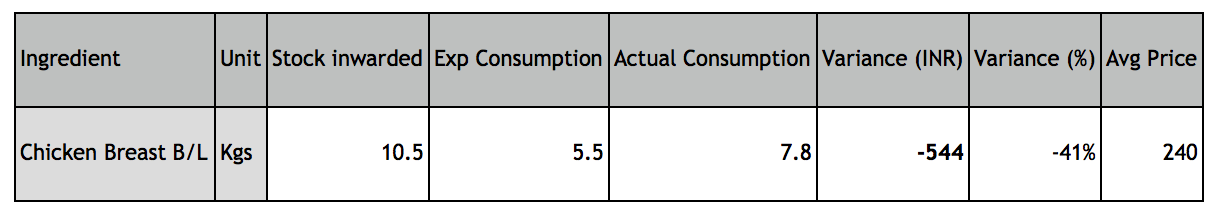

For Chicken breast boneless, we saw that there was about 2.3 kgs missing in a week, based on sale and expected consumption. Something like below (Avg price was around Rs. 240/kg). According to sales, we had sold roughly 36 dishes each using up 150 grams, leading to expected consumption of 5.5 kgs. Now why did we consume 7.8 kgs?

Now that we identified there was a massive variance (even post accounting for 95% yield), we had to get to the root cause. There are few possible reasons:-

- Wastage

- Theft/Pilferage/InHouse consumption

- Purchase Fraud (over billing)

- Over consumption — Recipe

As the purchase process was streamlined and trust in employees was intact, I ruled out first 3 options. An order arrived for one portion of “Thyme Grilled Chicken with Mashed Potatoes”. We paused and weighed the chicken piece that was to be used and it turned out to be 210 grams, a substantial increase of about 40%. We then weighed the other pieces, average was the same. For over 3 months we were losing money on every dish sold, no wonder reviews from customers were great ! Its time to fix it. When inquired why they couldn’t cut and prepare, chefs told me that the size of breast was as received and that it can’t be cut for the dishes we were selling. The issue here is simple — nobody monitored or measured, so nobody knew. Solution though, was trivial — we called up our vendors and asked them to supply smaller breast sizes in the weight range we wanted. To ensure this was fixed, we did the same exercise the next week and we brought down the variance to less than 4%. Well money saved is money earned.

There were numerous other such issues we solved over a period of time and we will cover those later. The journey was great but short-lived as we ran out of funds soon and founders decided to shut down in April, 2016. It was then Binu and I decided to build EagleOwl, to streamline the backend operations of this business, make it more efficient.

It took a lot more time to build than we had planned and there is more to do. But we finally managed to offer our beta version to 3 customers — a cake boutique (Butter Side Up), an ice-cream startup (Artinci) and a Bangalore based cloud kitchen (they are yet to start using it). What was heartening was the feedback from them so far and inquiry for next set of features. Thanks Pavithra and Aarti for your valuable feedback.

We request you to spread the word to your friends and connections to avail a free trial of our offering. We are ready to take orders.

Learn how to grow with EagleOwl. Our restaurant management system can help optimize your finances and increase your restaurant’s net profit by at least 25%. Contact us now to schedule a free demo!