The swanky restaurant you see from outside is full of activity, classy interiors adorning the walls, customers munching away with glee, well-dressed waiters treating you like demigods and running around like hares, the POS machine continuously churning out thermal prints — and you must be thinking “Ah, this looks like great business, why don’t we start one ?”

Almost every second person you meet will have one of these three wishes

- Start a restaurant

- Write a book

- Make a movie

And I guess #1 tops the list for most. Blame it on outward appearance of opulence, glamour and fast money. Wait till you start one or talk to any restaurant owner to know what happens “Behind The Scenes”. This applies to both the online and offline versions.

Starting the restaurant is the easier part, running it is a nightmare. All the glitz and glamour will vanish and you will soon face the reality, its real tough out there and hot !

Restaurants serve you food and it must be good — this is the number one priority. You compromise on this and you are doomed for failure (statistically 60–70% of restaurants close within 1.5 years of operation)

Food Costing

In this article, we will focus more from operational expenses, specifically food cost of a restaurant and how it ideally needs to be tracked and controlled. The top two costs for any restaurant is cost of ingredients plus employee salaries (in India this is relatively less). In some countries employee salaries might be more than COGS, due to minimum wage acts. Food cost ideally should be within 35% of sales. That it to say, you need to price your dish in such a way that it is approximately 3 times its cost of production for you to have justifiable returns.

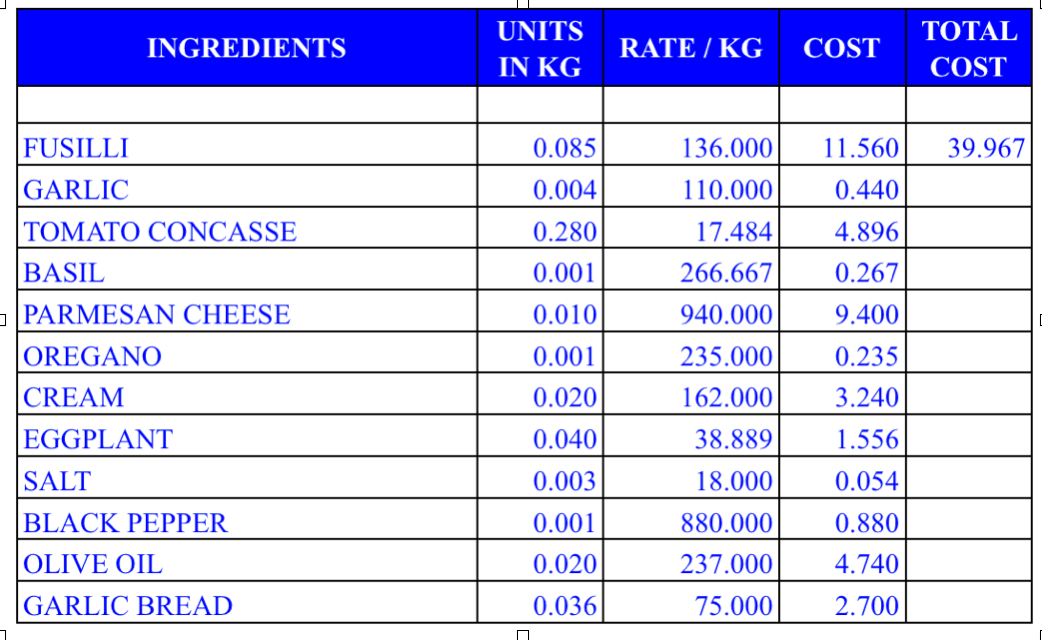

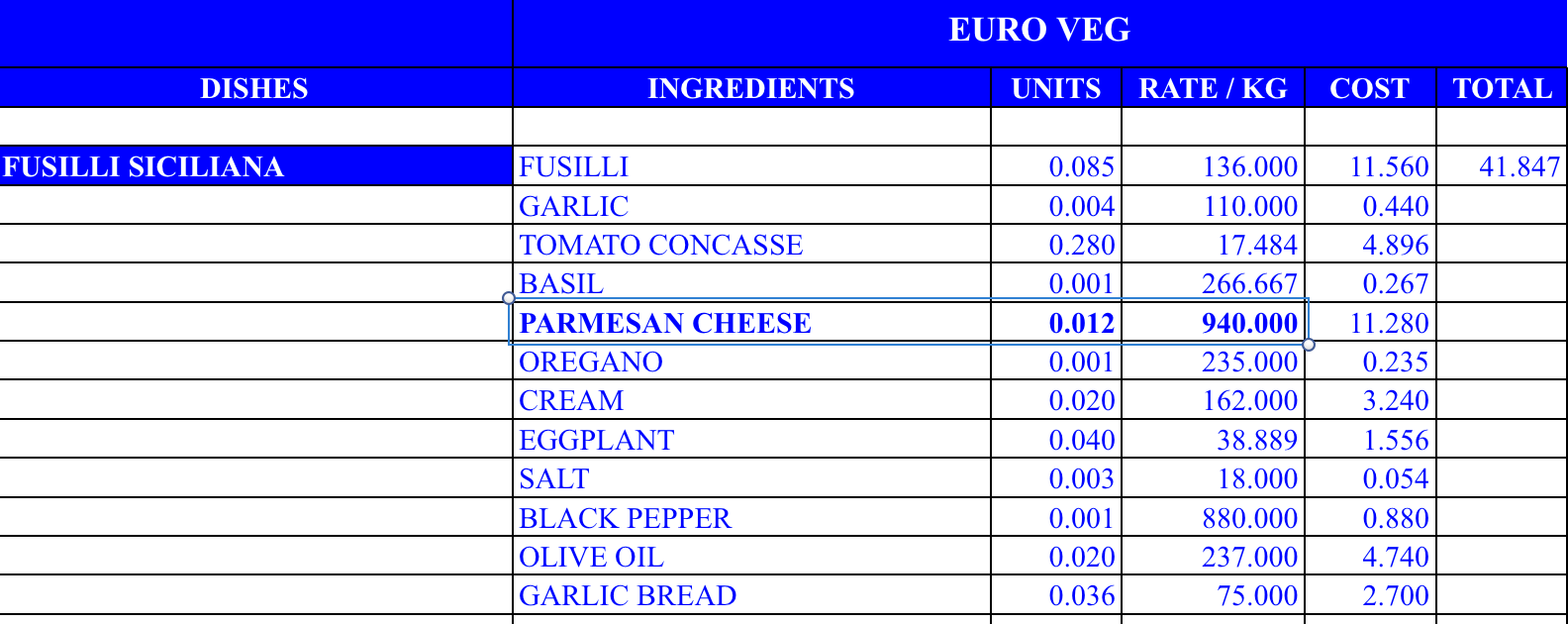

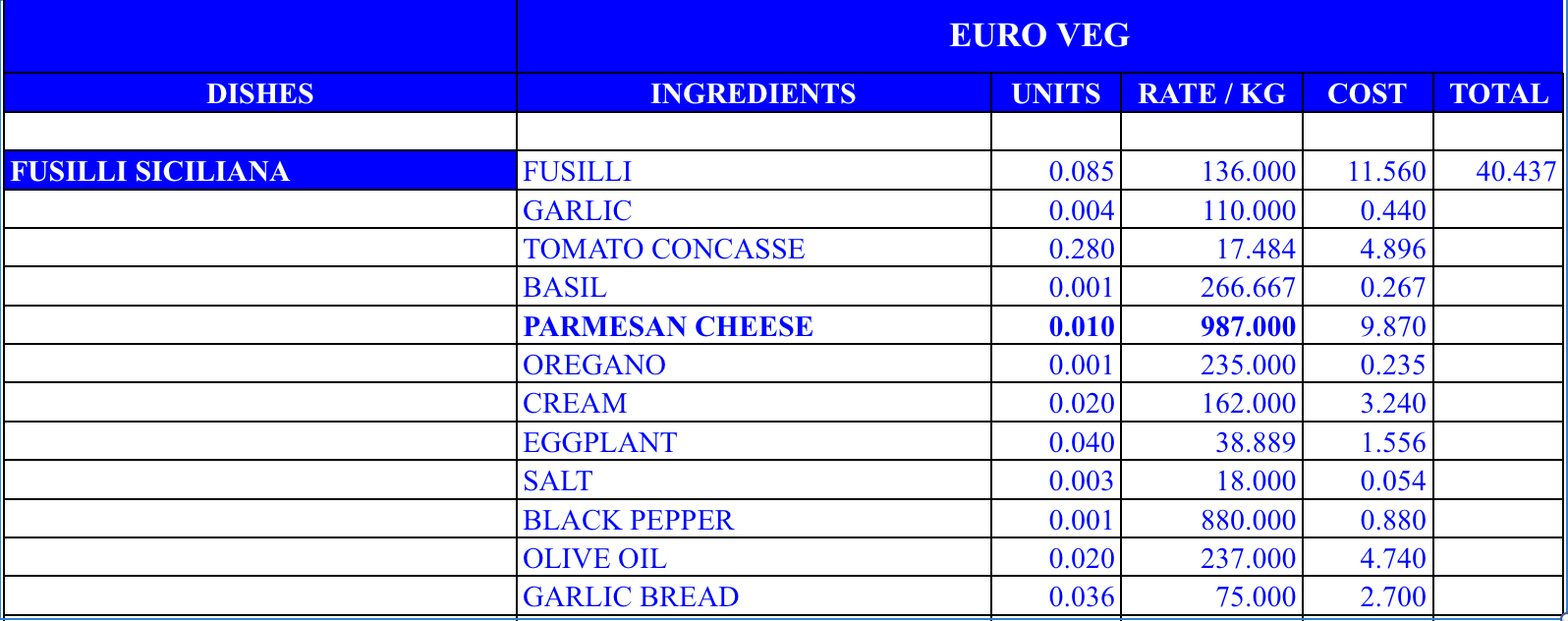

Let us take a common dish, say Fusilli Siciliana. Roughly the ingredients would be as shown, with units and cost, adding up to the total cost of the dish. A typical recipe will look something like this.

Firstly, most restaurants don’t necessarily prepare recipes; that’s still the fundamental problem — it is still the eye-ball measures with ball park estimate of what it would cost. Without knowing what their product will cost, they decide their selling price. Let us take a parallel industry that has matured over the years and uses a recipe for its products.

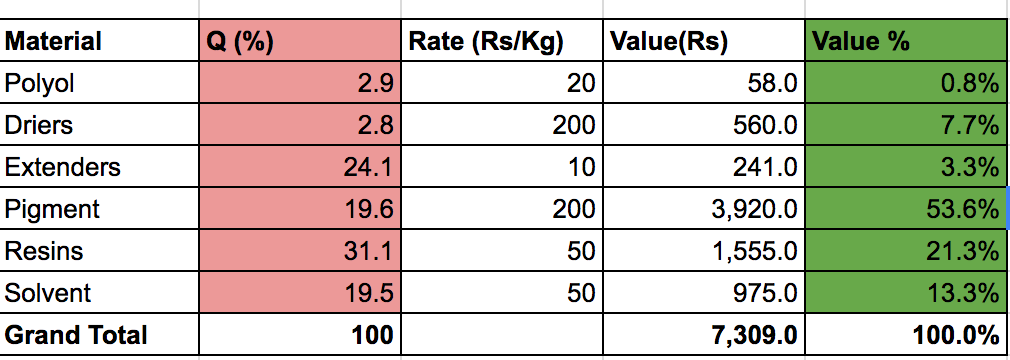

A paint manufacturer would ideally need three essential components — Pigment, Binder and Solvent in some ratio, apart from additives, extenders, emulsions, etc depending on the segment. Shown below is a sample paint recipe (Thanks to Mr. Gurumoorthy, Chemical Engineer, ex-Asian Paints). Now, there is an essential ingredient Titanium Dioxide which is expensive and say forms bulk of the overall cost of produce. We have chosen this ingredient, as it fluctuates highly, imported into India.

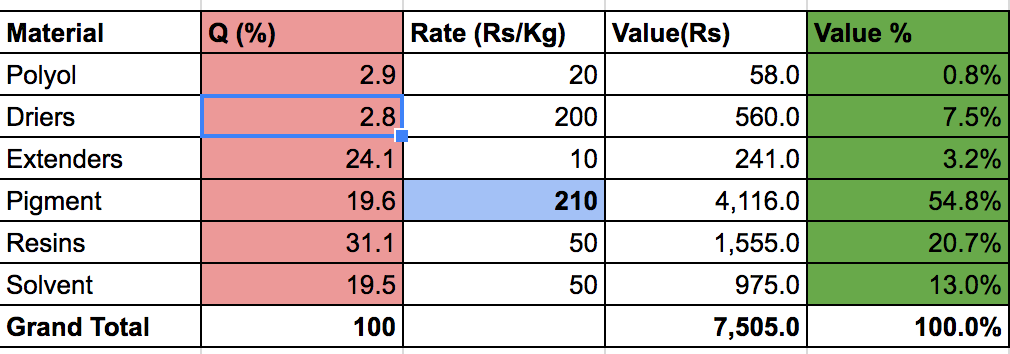

Let us do a breakdown of cost for a sample paint recipe.

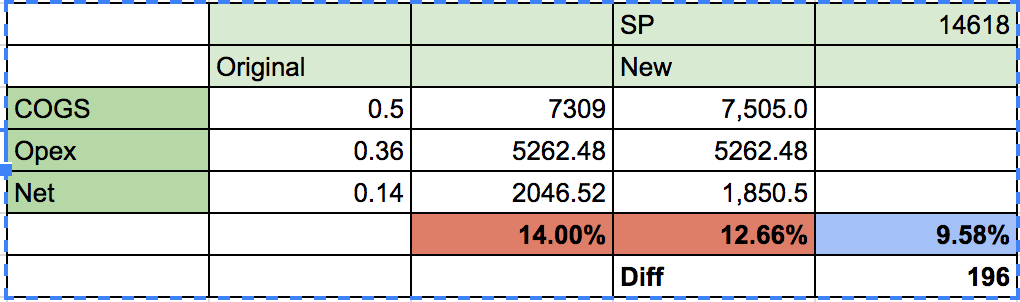

And assume Titanium dioxide accounted for about 5% increase in costs (pigment). There is a difference of approx 10% in your net profit, assuming a 5% increase in one component. The paint industry is relatively matured and uses computerised mechanism to use the ingredients at the right mix, the fluctuations are quite less compared to restaurant ingredients, and almost all ingredients have shelf life of at least 6 months. This effectively leads to exact calculation of their production cost and expected margins. If the industry didn’t adopt scientific mechanisms coupled with use of technology, it is quite likely that Asian paints (with 50% market share) in India, will lose Rs. 196 for every 10 litres sold by them (assume that 10 litres of this product is sold at Rs.14618). The market share translates into at least 12,000 Crores, and if we take below numbers, they should be selling approximately, 80 lakh litres an year, and if they lose 196 per 10 litres, it amounts to a whopping 15.68 Croresan year. Too costly a mistake to make. Paint manufactures are smart, they don’t..

Back to Restaurant

The above fusilli recipe would approximately cost Rs.40, depending on the average prices of ingredients during that period. And you could price it comfortably at say Rs.150 to make a 73% Gross Margin. The easier part is done, the ingredients in restaurants are like stocks listed on markets. They fluctuate, though not as often as stocks, on a daily or monthly basis, depending on region, state. So will the selling price and even your recipe might not be the same across outlets. Will your selling price ensure your profit is sacrosanct ? No.

Let’s say, you sell about 200 plates of food a day, at an average of Rs. 150, translating into 30,000 a day or 9 lakhs a month. Assume your net profit is 14%, i.e 1.26 lakhs a month.

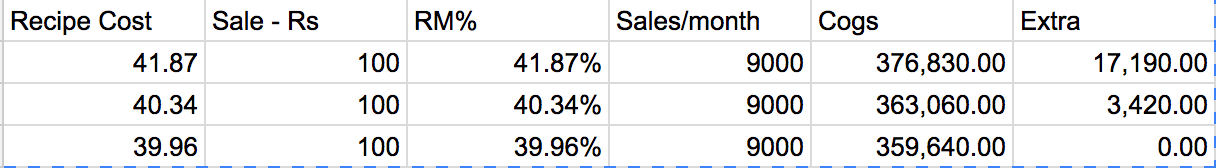

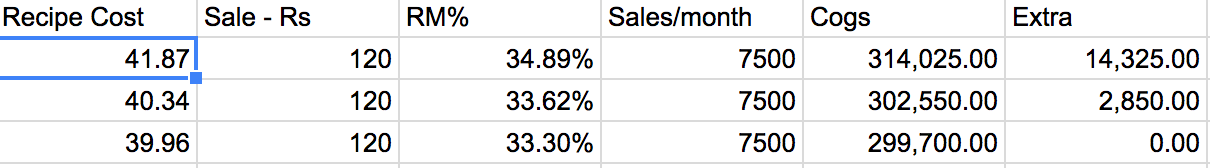

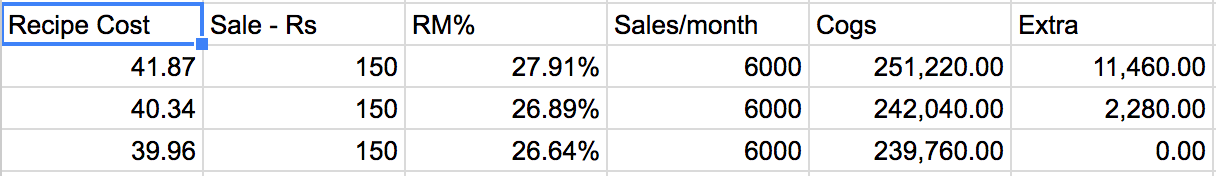

Assume the cost of parmesan cheese, which is quite expensive, increased by just 5%. Now there is a difference of .47 increase per plate, or another use case of someone adding 12 grams of cheese instead of 10 grams on a regular basis, translating into 1.88 Rupee increase. For ease of calculation, lets assume you sell 200 plates of this dish everyday, translating into 6000 a month (i.e 9 lakhs revenue). And we have taken just one ingredient (where error has crept in) for simplicity.

A simple 2% reduction in food cost (which is generally the wastage) will save you 18000 a month or a good 2.16 lakhs an year, assuming a modest 9 lakhs of sale in a restaurant. If you add this to your net profit, it will be 14%.

The estimated food wastage in India is a whopping 50,000 Cr an year and it is about $159 Billion in US alone, with restaurants contributing a healthy percentage to these numbers. By adhering to your recipes and adjusting your supply chain, every restaurant can not only increase their net profits by anywhere from 10–35%, but also contribute to lesser wastage.

Tables below retain sales at 9 lakhs, with varied selling prices (100–150), adjusting for various food cost percentages and changing num of plates per month. The column ‘extra’ is the savings per month that is potentially getting lost in most restaurants, which could be added to your net profits. Two conditions are taken into account, the bottom one listing the current recipe cost, the one above is for a 5% increase in parmesan cheese and the one on top is an extra dose of 2 grams to the quantity (these are typical use cases in a restaurant) and nobody notices..

Restaurants deal with highly perishable items unlike many other industries. They also face challenges with fluctuating prices eating into their margins. Purchase orders are linked to consumption patterns and that can be tracked only if you have a proper recipe and track your food cost week on week. If these complexities aren’t enough food ingredients have yields which will further dent your margins if not tracked and accommodated in your calculations.

The math has remained quite simple, all a restaurant needs will be recipes, opening and closing stocks, sales and purchase details. Punch them in and you will save millions in the long run.

PS: Introductory note on backend operations, will cover yield, shrinkage, inventory, wastage and related areas in my next article. You can write to me for any insights into restaurant backend operations.

Learn more about the importance of restaurant operational manuals.